Tags

Related Posts

Share This

Printing Color Displays

by Henry Freedman

Printing Electronic Color Displays

Developments in low-cost electronics manufacture, coupled with advances in printing and imaging technology, will open opportunities in electronic displays-some using adaptations of traditional print technology.

This isn’t unprecedented. At the arrival of printed circuit boards in the 1960s, photo emulsions, step-and-repeat and etching processes used in litho platemaking were adapted to foster growth of a large electronics industry. Today, technologies such as nano inkjet are positioned to grow into applications supporting low-cost large computer display production and even high-definition television displays (HDTVs).

One early researcher into related new approaches to printed color displays is Sarnoff Corp. The former RCA Laboratories, founded by David Sarnoff, developed color televisions and the CRT picture tubes that brought computers and monitors to the masses. Sarnoff now has a great interest in printing, hitching some of its research resources to produce flexible TV screens using modified versions of conventional printing.

Many firms are entering this emerging arena. The recent ID TechEx Printed Electronics Forum featured nearly 50 exhibitors, including several firms with traditions in graphic arts film-Agfa, BASF, Ciba, Dimatix (a Fujifilm unit), DuPont and Sun Chemical. Their presence is no coincidence.

OLEDs & Imaginative Flat Panel Uses

Kodak is also working in this arena, developing technologies to put organic materials to use for Organic Light Emitting Diode displays (OLEDs). Kodak’s work in OLEDs, the subject of a Dec. 27 feature in the Wall Street Journal, might be seen as a variation on film production, with the flexible plastic substrate in the role of a film base. The exposure systems for printing on the film is comparable to ultra-high resolution imagesetting. OLEDs are used typically for less demanding applications, such as lower resolution displays for cell phones, than for the higher-end transistors made with other Sarnoff technologies. In the latest efforts at adapting printing to producing electronics, Sarnoff is primarily focusing on the production of transistors on a flexible substrate.

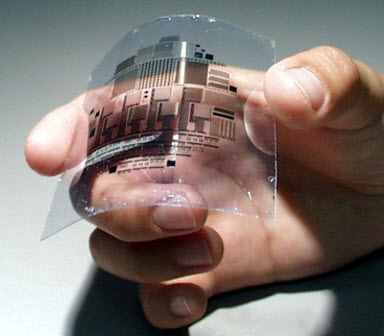

Sarnoff’s newest printed displays could potentially exceed today’s typical computer displays. To date, screen and flexo printing processes have been used to print data entry buttons on flexible plastic surfaces, used purely for mechanical interface. Now the firm says it is nearing a new potential: printing organic transistors for delivering the image onto the display itself-like an inkjet spray of the organic material on a roll-to-roll web of transported plastic substrate. The process can be run at a lower temperature and in an environment that is more forgiving than the cleanroom used in other approaches.

Sarnoff is looking to print unbreakable, reflective, flexible plastic Liquid Crystal Displays (LCD) that are capable of displaying both a printed page, full video, or a combination thereof. We may also see computer displays rolled up into pens (like mini window shades), video smart cards and multimedia presentations on paper-thin displays that follow contours of curved walls or other objects.

Subscribe to Henry Freedman’s Technology Watch newsletter Click here.