Tags

Related Posts

Share This

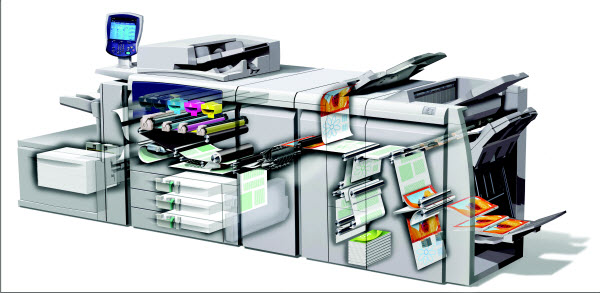

Xerox 700 Digital Color Press

by Henry Freedman

Toner Key to Hot Selling Mid-Range. Xerox rolls on with 700 digital color press.

Is it equivalent to the BMW 3 series?

When first announced at Drupa 2008, Xerox garnered over 100 sales of its new model 700 mid-level production color press. No doubt sales are headed north of 1,000 units, if past experience is any guide. Printers have figured out the value equation. Over the past few years, Xerox placed over 10,000 of its 40-ppm+ DC240/250/260 line (which uses related imaging technology).

Let’s see why the Xerox 700 Digital Color Press performs and sells like the BMW 3 series. The new 700 press arrives out of the box with a very broad suite of printing and binding configuration options. It prints on a wide range of substrates accepting both coated and uncoated papers up to a 300-gsm weight, and is most capable of printing on a wide range of specialty materials. It uses a uniquely formulated toner that resists scuffing, so in many cases overcoating can be eliminated. Of great importance is Xerox’s market defining low-cost economics with a nicely configured model 700 coming in at under $100,000 including integrated finishing.

A new version of Emulsion Aggregate or ‘EA’ toner is a big part of the 700 image quality. EA toner particles are grown, not milled, providing key strengths in imaging and finishing—it’s Xerox’s “special sauce.” The latest EA Low Melt toner has been modified to deliver an attractive-looking matte finished color production print. The process of forming EA toner particles allows for greater participation of different chemistries, optimizing color reproduction and finishes. This was enabled by engineering a low melting point for the toner, around 60° C, for deforming and fusing to the substrate. This delivers a significant energy savings, while increasing uniformity of reproduction and run stability.

In the 700, the sheet does not dwell long in the fuser, since Xerox upped the speed to 70 ppm for process color. Yet it holds image register within 1 mm front to back. The EA Low Melt toner has another big advantage: It can also maintain a unification of charge in all ambient printing plant environments—worldwide. This means the platform delivers consistent quality globally. The model 700’s EA prints display good fine-line detail without streaking, smooth halftone transitions, bold colors and a nice matte finish. For some applications, it takes less EA than conventional toner to print an identical image! Tuning for the finish

Over the years, EA-type toner chemistry mixes have successfully delivered to market a wide range of finishes: matte, from the Xerox DocuColor 3535 released in 2003; gloss, from the EAHG model Docu-Color 240/260 series; and now a very pleasing matte on the 700. (Although DC 240/260 series output has never been called gloss, per se, you could reasonably characterize it that way.) It may also be possible to make an addressable toner, where the operator could dial a gloss level without requiring a coater, more easily adapting to customer preferences. Toner finishes may be part of your future variable-imaging print mix.

Subscribe to Henry Freedman’s Technology Watch newsletter Click here.